DeepForge: Leveraging AI for Microstructural Control in Metal Forming via Model Predictive Control

This study presents a method for microstructure control in metal forging that combines Model Predictive Control (MPC) with a newly developed machine learning model called DeepForge. Using 1D convolutional neural networks and gated recurrent units, DeepForge predicts microstructural changes from surface temperature measurements, providing a novel approach to improving forging quality and precision. By integrating real-time control via MPC, this research demonstrates the ability to dynamically adjust process parameters for optimised microstructural results.

Details

Type of Work: Scientific Publication

Main Author: Jan Petrik

Affiliation: ETH Zurich

Co-Authors: Markus Bambach

Date: 25th February 2024

Journal: Journal of Manufacturing Processes

Online: Arxiv

Gallery

-

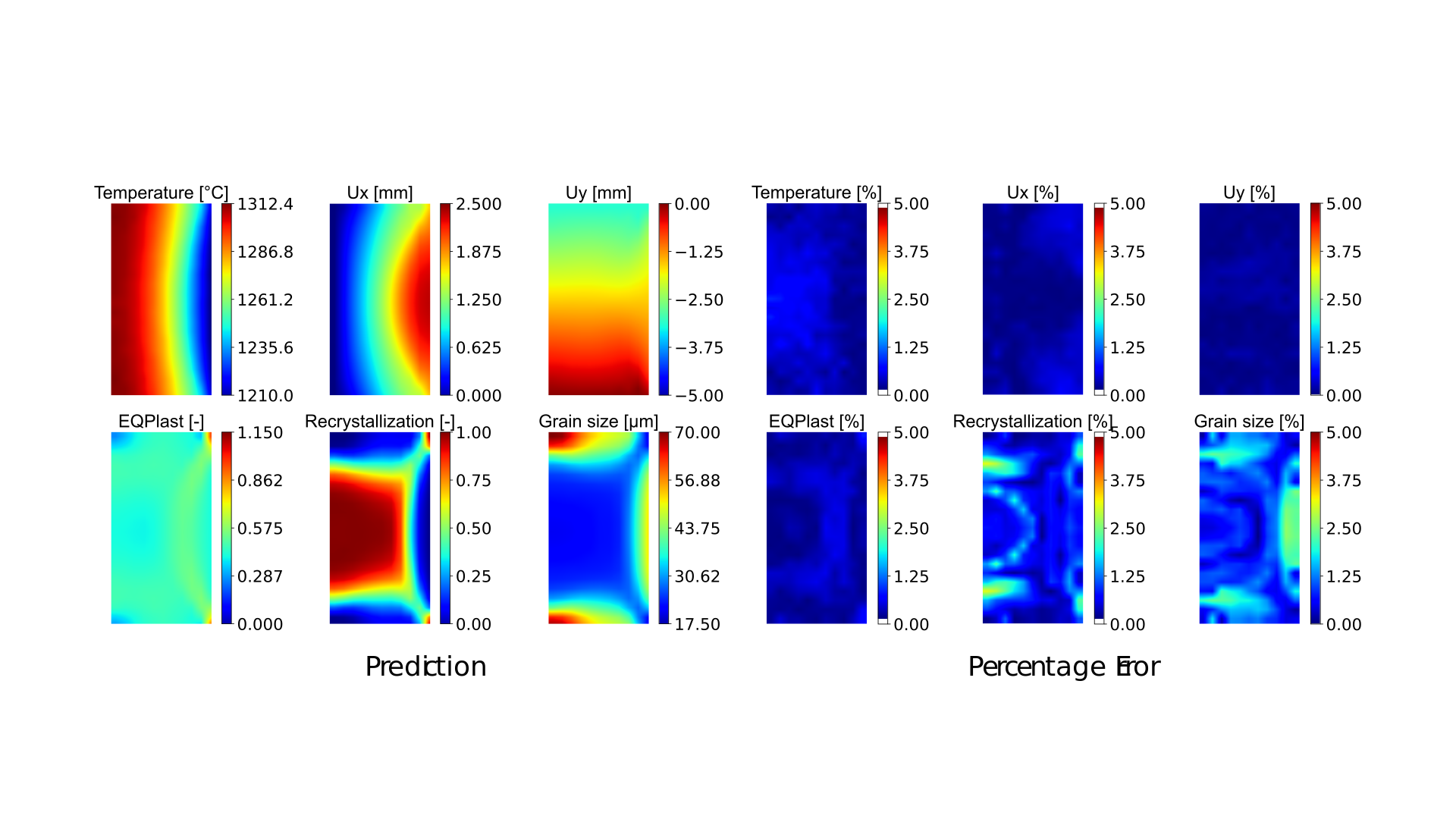

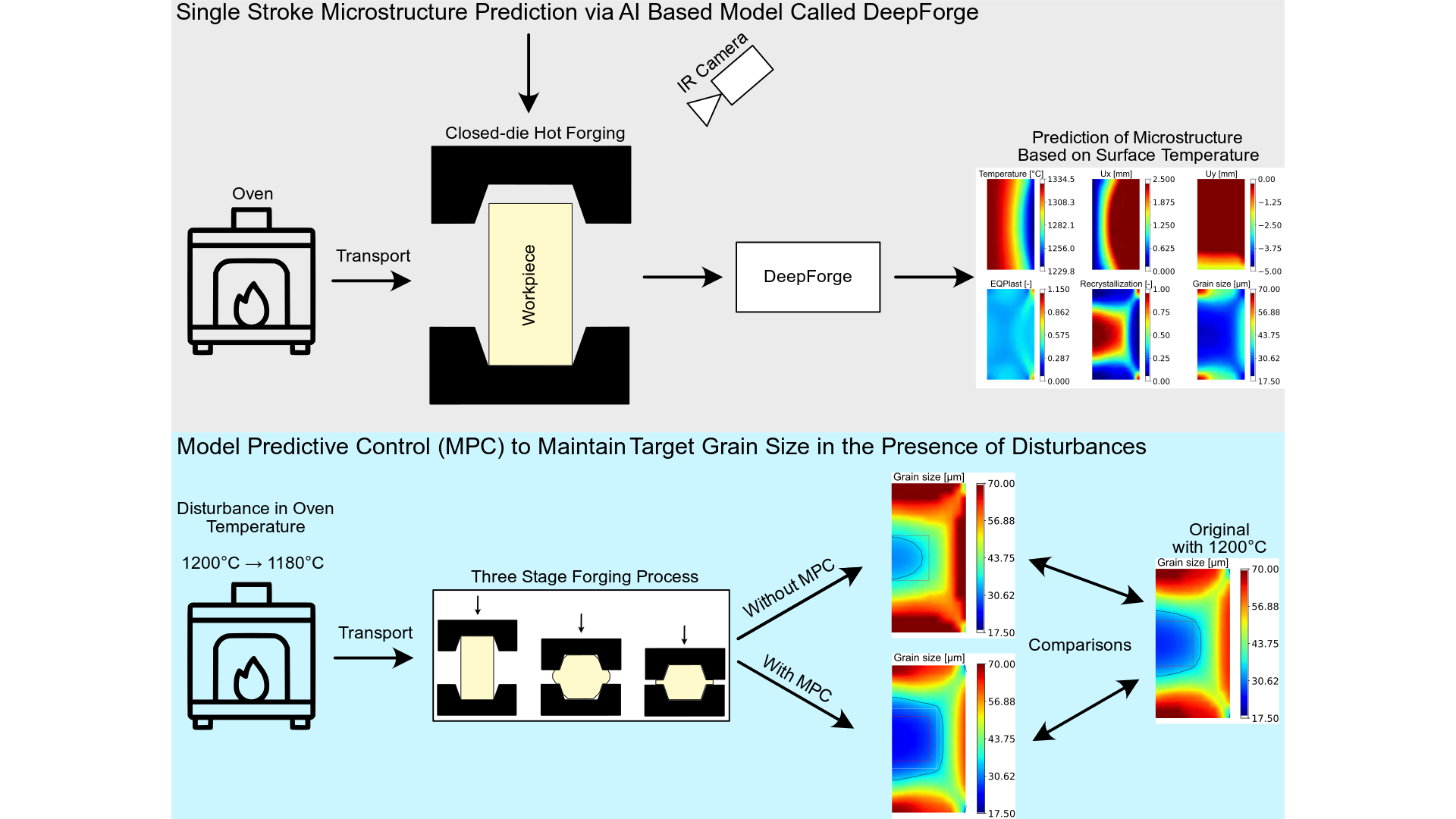

Graphical abstract showcasing DeepForge's capability to predict the microstructure of a workpiece during forging, using only surface temperature measurements. Additionally, it highlights the integration of Model Predictive Control, enabling real-time adjustment of process parameters to attain specific microstructural characteristics. -

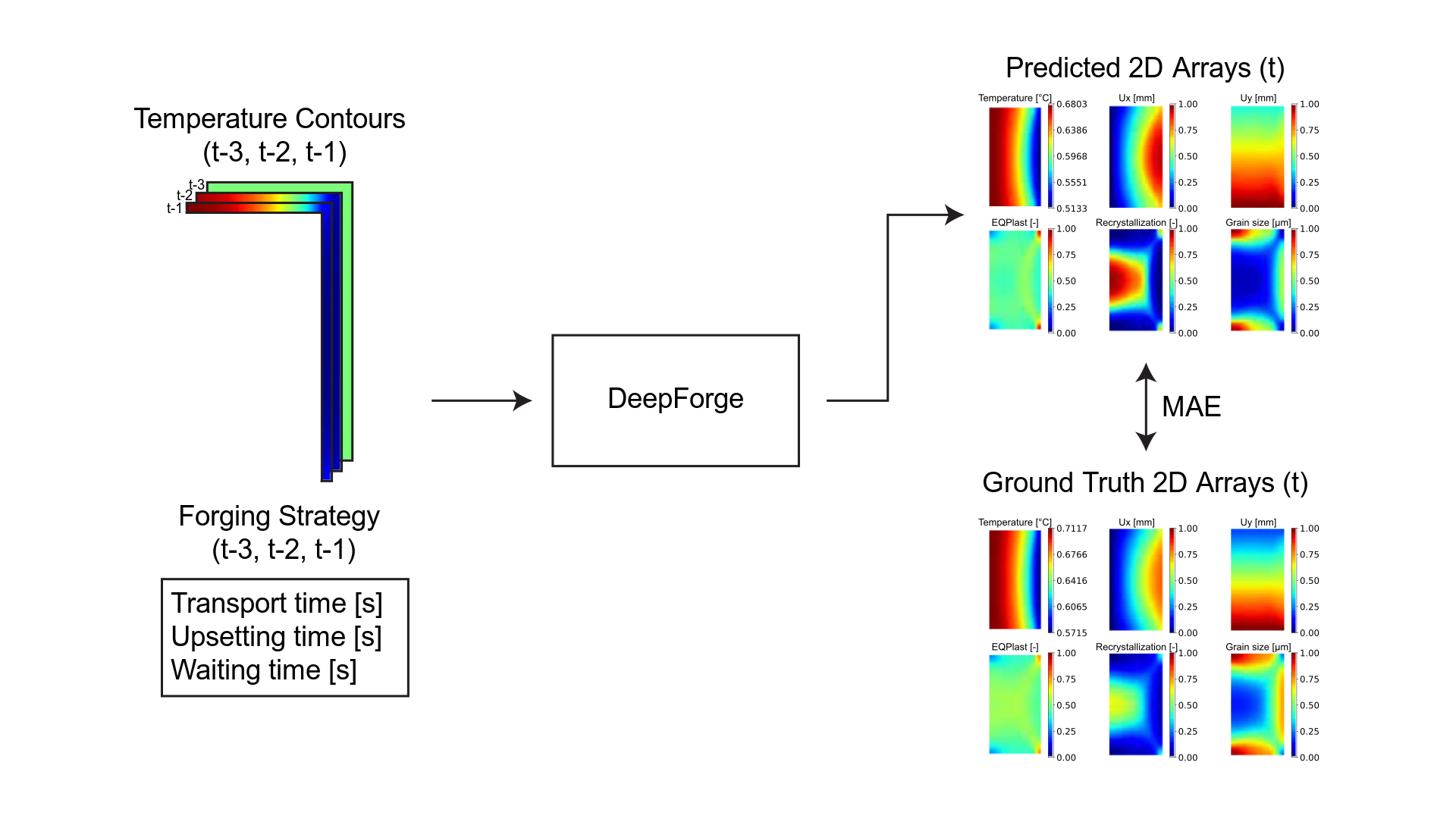

DeepForge's training workflow uses past surface temperatures and a forging strategy as inputs, defaulting initial temperatures to 0 if unavailable. It reconstructs 2D microstructure arrays of the part, considering the forging effects. The model is refined through comparison with actual data using Mean Absolute Error (MAE).