CrystalMind: A surrogate model for predicting 3D models with recrystallization in open-die hot forging including an optimization framework

This paper presents CrystalMind, a surrogate model designed for fast and accurate 3D prediction of deformation and recrystallisation of workpieces undergoing open die hot forging in 3D. Using machine learning, specifically MLP (Multi-Layer Perceptron) and PointNET++ architectures, CrystalMind significantly reduces computation time compared to traditional approaches such as FEM simulations.

Details

Type of Work: Scientific Publication

Main Author: Jan Petrik

Affiliation: ETH Zurich

Co-Authors: Syed Irtiza Ali, Martin Feistle, Markus Bambach

Date: 1st December 2023

Journal: Mechanics of Materials

Online: ScienceDirect

Gallery

-

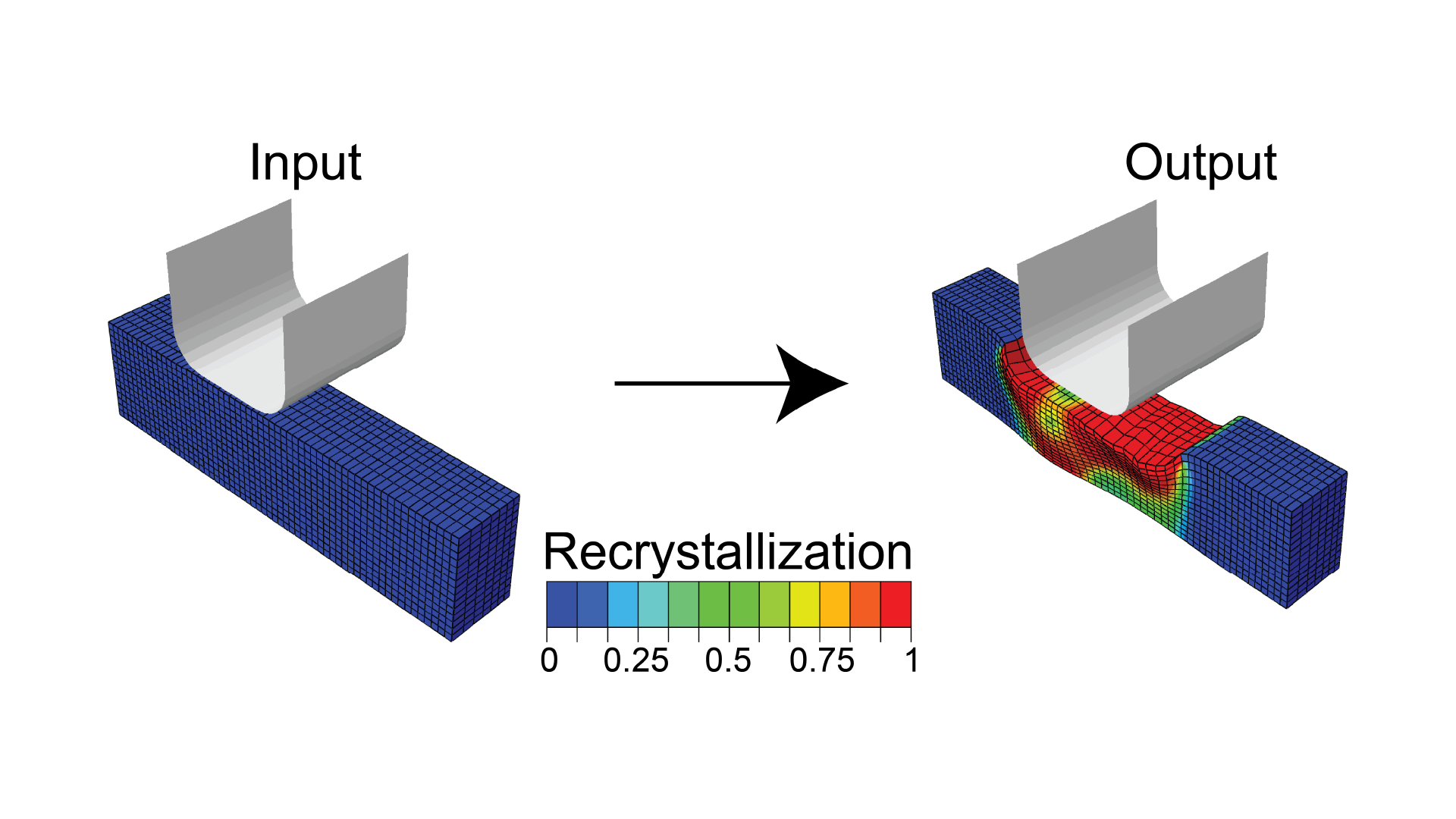

The representation of both the input and output from the Abaqus simulation is showcased, highlighting the mesh deformation and recrystallization process. This information was instrumental in training the AI-based model known as CrystalMind. It's also important to mention that due to axial symmetries, the simulation only required one quarter of the workpiece. -

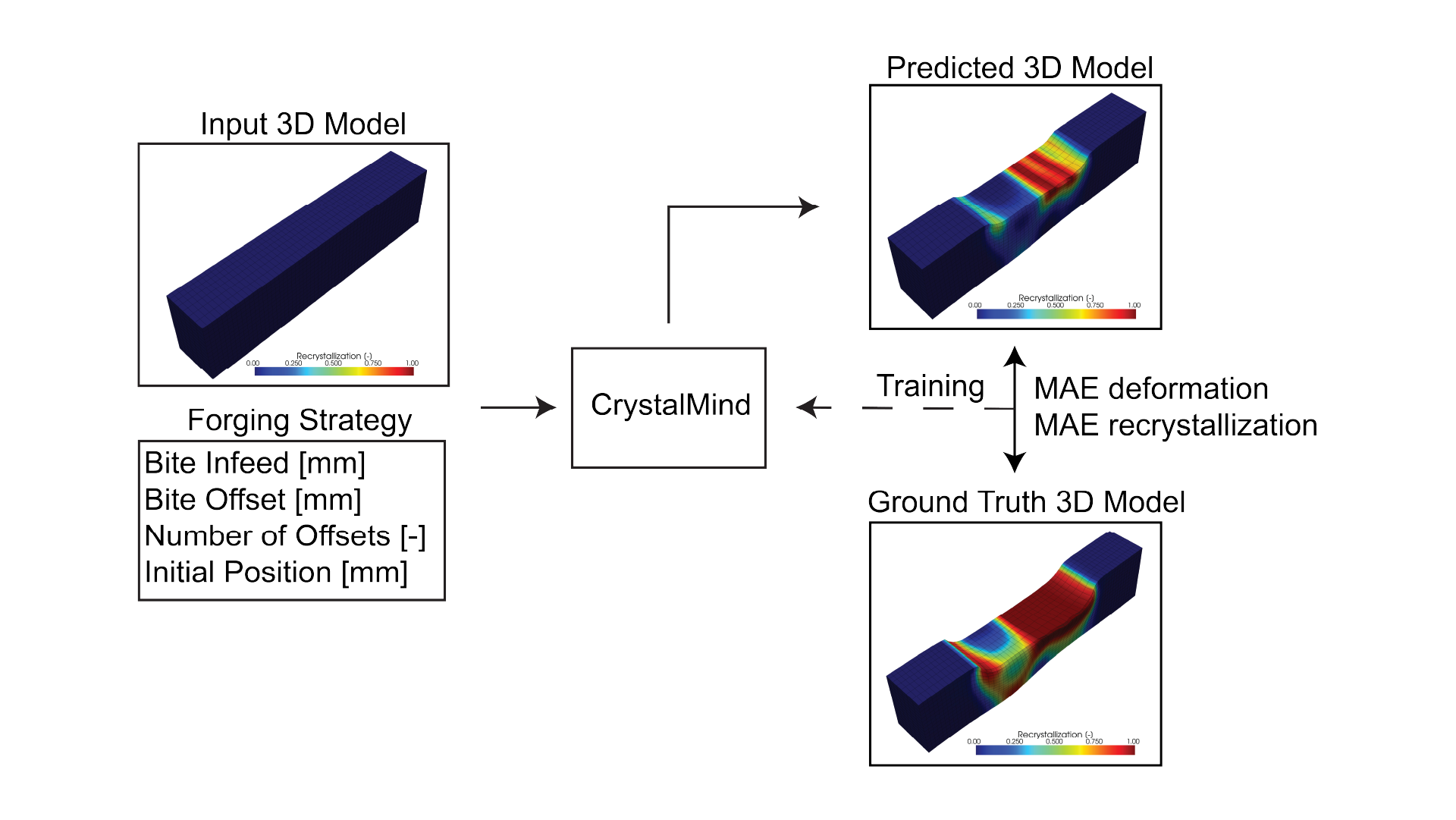

Training workflow of CrystalMind. The architecture accepts as input a 3D model and a forging strategy defined as a 4D vector. Afterwards, it reconstructs the 3D modelbased on this input, incorporating a forging stroke according to the 4D vector. The resulting prediction is compared with a ground truth 3D model using two loss functions basedon mean absolute error (MAE). Through multiple epochs, the total loss is backpropagated to the architecture for training. -

Video of a GUI demonstration built on CrystalMind, where users can specify the forging strategy and input geometry. In just a few milliseconds, they receive feedback on the recrystallization and deformation outcomes of a workpiece.