Development of Smart Experimental Facilities

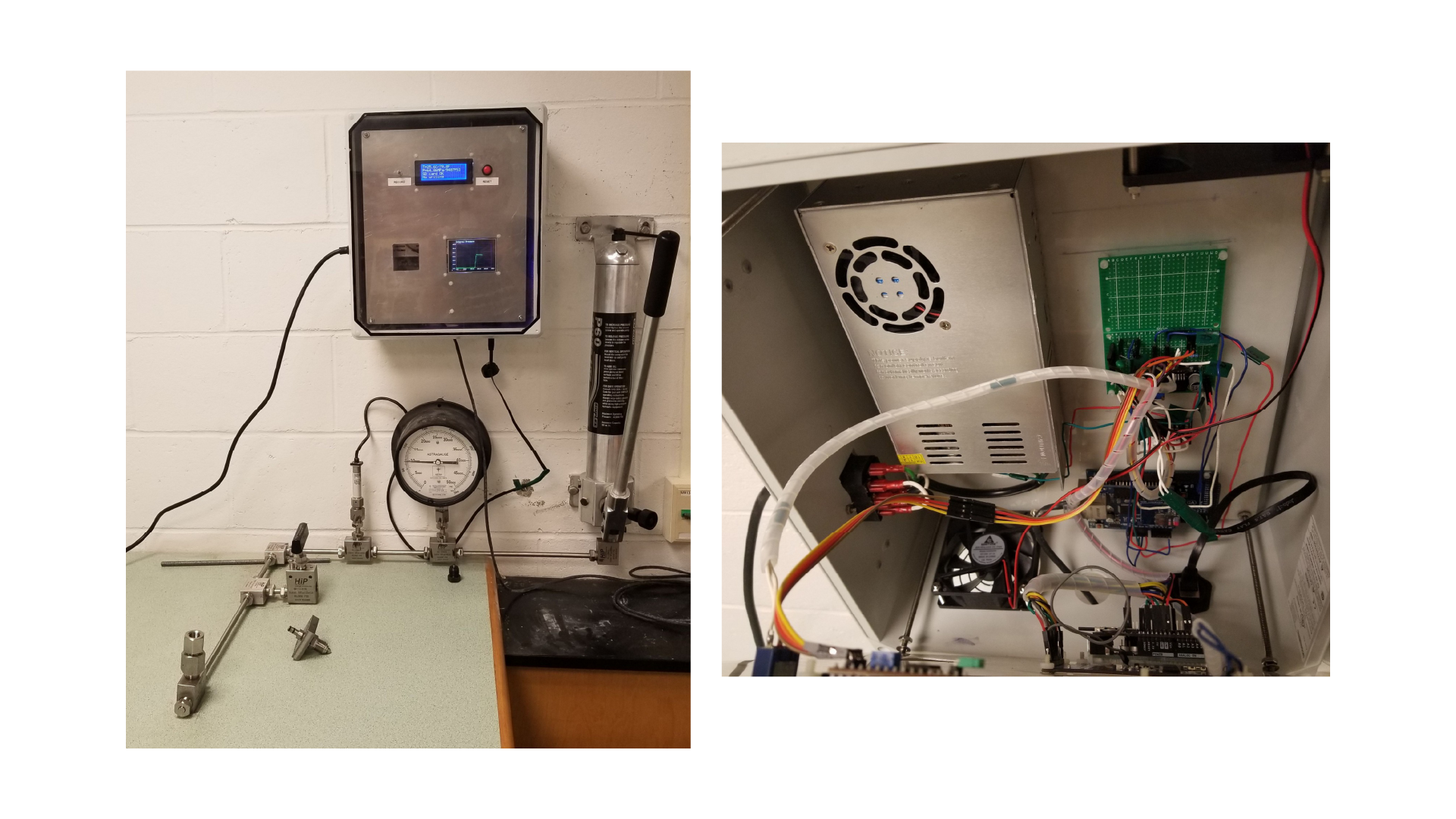

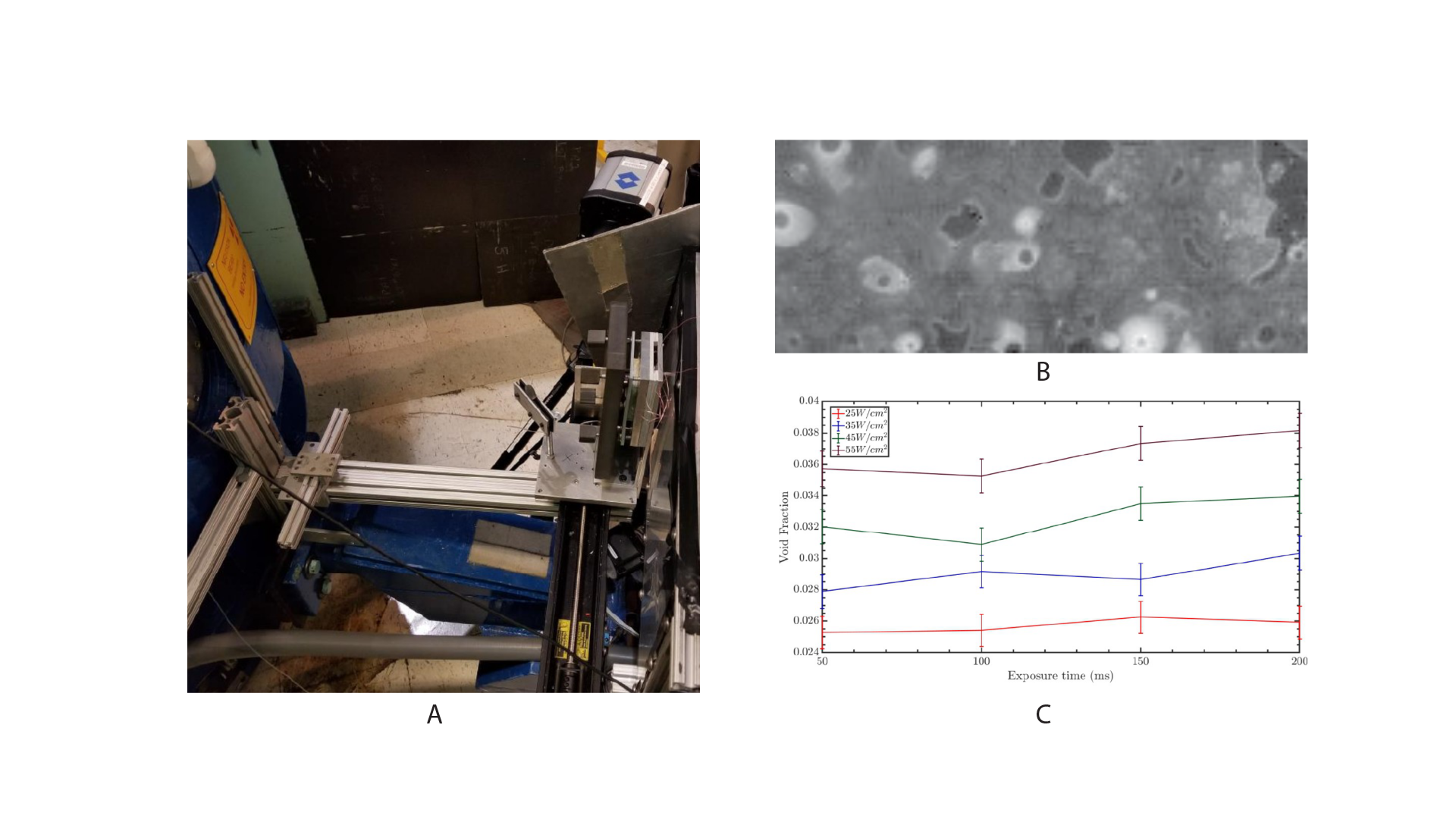

During the seven-month stay at MIT, the focus was not on the development of new nuclear fuel cladings, where reliable and intelligent experimental facilities play a crucial role. The primary facility developed was aimed at measuring the burst pressure of pellets. A thermometric device for neutron imaging of two-phase flow was also developed.

Details

Type of Work: Experimental

Main Author: Jan Petrik

Affiliation: MIT

Supervisors: Bren Phillips

Date: 2018

Journal: None

Online: None