Modelling of Manufacturing Processes via Machine Learning Algorithms

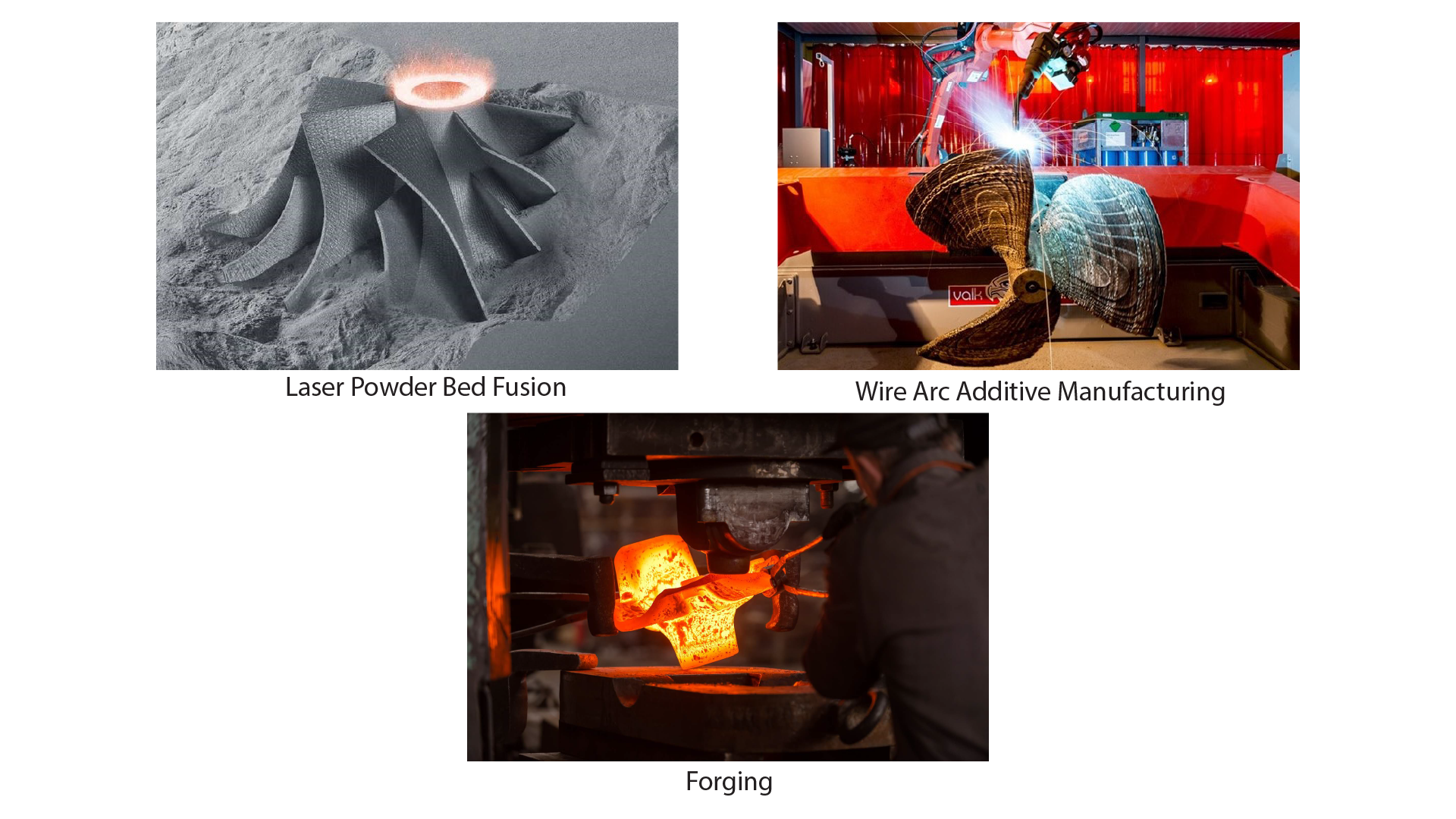

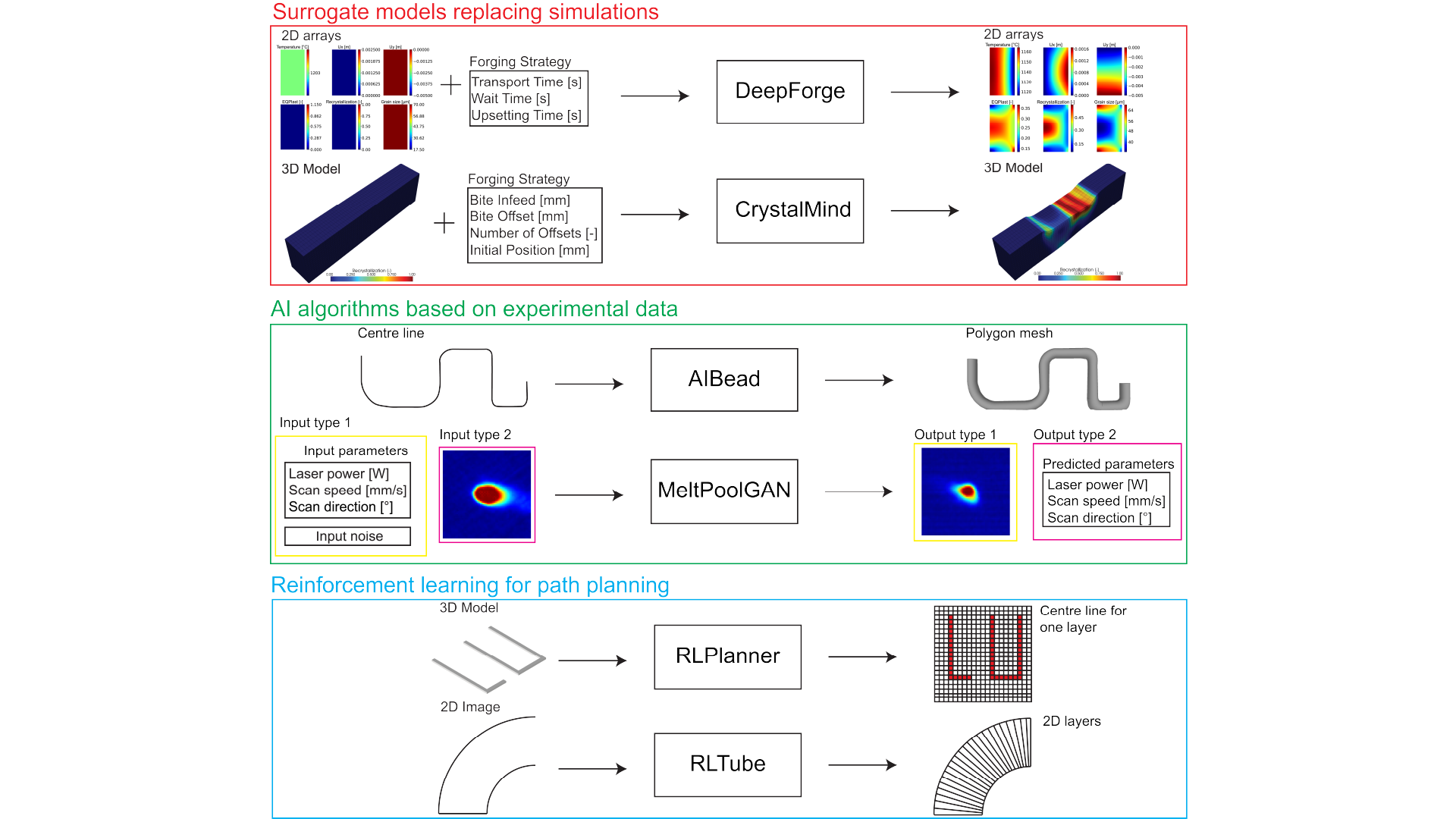

This dissertation explores the use of machine learning techniques in manufacturing to enhance efficiency and quality. It investigates the real potential of AI through addressing three challenges: surrogate modelling, AI driven by experimental data, and reinforcement learning. Six AI models developed within this study tackle these issues. DeepForge and CrystalMind, as surrogate models, offer rapid prediction capabilities, notably reducing the time for optimizing forging processes from years to minutes. MeltPoolGAN and AIBead, empirical AI models, leverage real-world data to refine predictions in complex manufacturing tasks, with MeltPoolGAN notably improving melt pool image classification. RLPlanner and RLTube demonstrate the application of reinforcement learning in path planning for Wire Arc Additive Manufacturing, optimizing process parameters efficiently.

Details

Type of Work: PhD Thesis

Main Author: Jan Petrik

Affiliation: ETH Zurich

Supervisor: Prof. Dr. Markus Bambach

Co-Examiner: Prof. Dr. Wolfram Volk

Date: 20th October 2023

Journal: Six Publications in Journals

Online: ResearchCollection

Gallery

-

Closed and open loop systems tailored for manufacturing processes, incorporating Artificial Intelligence (AI) models. These AI models are developed based on simulation or experimental data from the manufacturing systems. Furthermore, these AI models can be used within an optimization algorithm to improve manufacturing processes. -

Summary of six AI-based models deployed within the dissertation. Their more detailed description can be found in my Portfolio.

Related Projects

-

Advancing Sustainable Energy: Combining Carbon Capture and Air Storage Solutions

-

Learning Unsupervised Shape Recovery from Images

-

Generative AI for Optimization of Laser Powder Bed Fusion

-

Adaptive Path Planning for 3D Printed Tubes in Additive Manufacturing

-

Coming soon: AI-Powered Microstructure Optimization in Metal Forming

-

Optimizing Path Planning in WAAM with Reinforcement Learning

-

AI-Driven 3D Weld Bead Reconstruction in Wire-Arc Manufacturing